Quality Control

At Noves Technologies, quality is not just a process—it is a commitment embedded into every stage of our operations. We understand that industries like aerospace, medical, defence, and automotive demand components where even the smallest deviation can impact performance. That is why we follow a zero-compromise approach to quality control, ensuring every part we manufacture undergoes rigorous inspection, testing, and validation. Our advanced measurement systems, precision tools, and internationally recognized standards guarantee dimensional accuracy, material integrity, and long-term reliability. From raw material selection to final delivery, every step is monitored with strict protocols, giving our customers complete confidence in the durability, safety, and precision of our components. At Noves Technologies, quality is not just maintained—it is continuously improved to exceed expectations and set new benchmarks in engineering excellence.

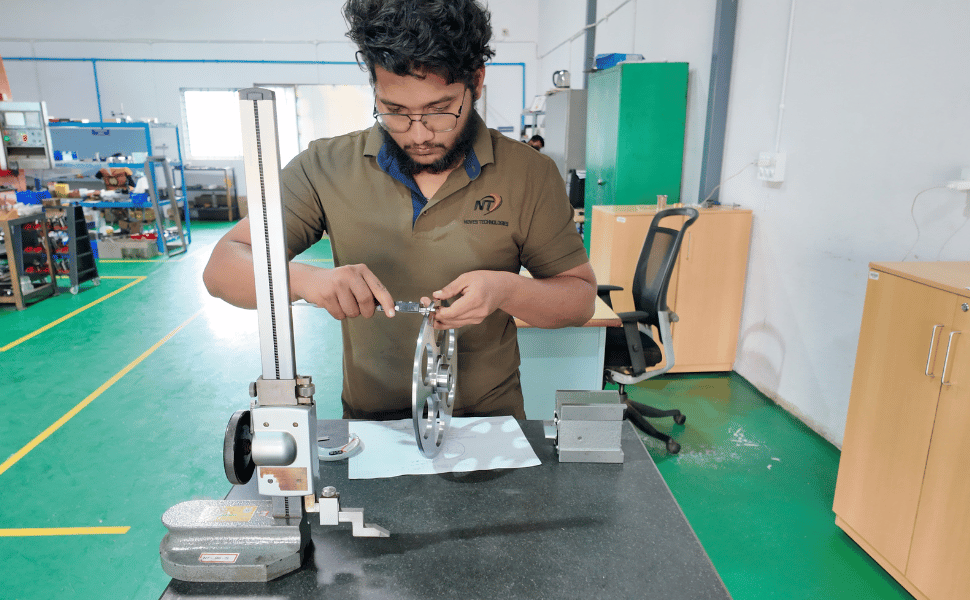

Inspection Equipment

At Noves Technologies, we rely on advanced inspection equipment to maintain the highest levels of accuracy and quality. Every component we produce undergoes precise measurement and validation to ensure it meets global standards for aerospace, medical, defence, and automotive applications. Our modern inspection tools enable us to achieve tight tolerances, superior finishes, and consistent performance across all products.

Our Inspection Capabilities Include:

-

Coordinate Measuring Machines (CMMs) – For high-precision dimensional checks.

-

Profile Projectors – To verify complex shapes and geometries.

-

Surface Roughness Testers – Ensuring flawless finishes.

-

Height Gauges & Vernier Calipers – For accurate linear measurements.

-

Hardness Testers – To confirm material strength and durability.

-

Specialized Gauges & Fixtures – For custom inspection requirements.

Our Commitment

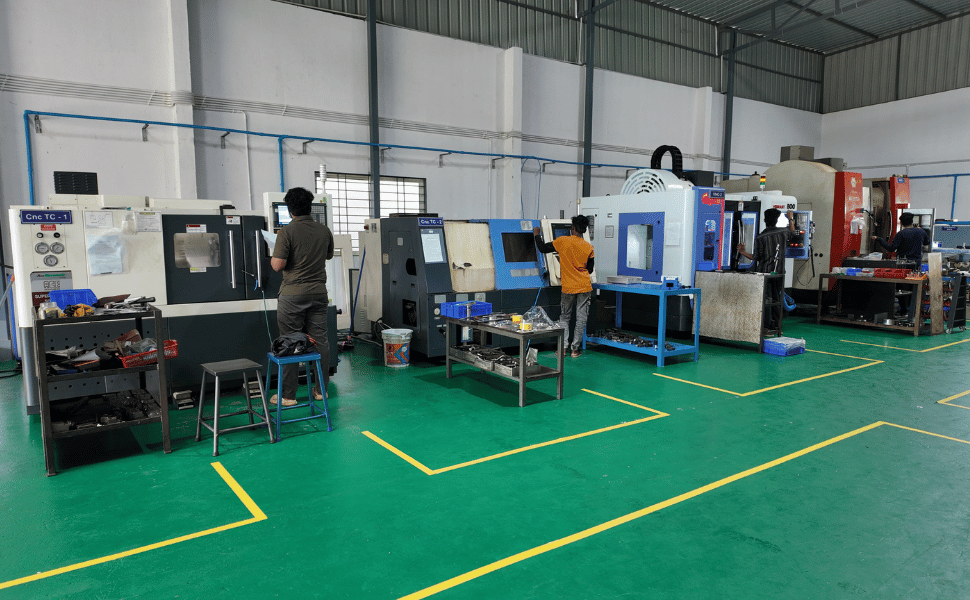

At Noves Technologies, we are dedicated to delivering far more than just precision components—we deliver trust, reliability, and engineering excellence that drives industries forward. Our commitment is not limited to manufacturing; it is woven into every stage of the journey, from initial design and development to production, inspection, and final delivery. We recognize that in industries such as aerospace, medical, defence, and automotive, even the smallest detail can make the biggest difference. That is why we embrace a zero-defect philosophy, ensuring that every component that leaves our facility meets the most demanding global standards.

With over 15 years of industry expertise, we continue to invest in modern infrastructure, advanced CNC technology, and skilled professionals who share our passion for precision. Our promise goes beyond quality—we are committed to on-time delivery, cost-effectiveness, and long-term partnerships built on transparency and mutual growth. By fostering a culture of continuous improvement, innovation, and customer focus, we strive not only to meet expectations but to consistently exceed them at every step.

-

Uncompromising Quality – Every component is inspected and tested for accuracy and durability.

-

On-Time Delivery – Projects executed with efficiency and timely execution.

-

Innovation & Technology – Adopting advanced CNC machining and modern practices.

-

Customer Satisfaction – Tailored solutions designed around client needs.

-

Global Standards – Compliance with international engineering and safety norms.

-

Continuous Improvement – Constantly upgrading processes to exceed expectations.

Our Quality Standards

Our Quality Assurance Pillars

At Noves Technologies, our quality assurance stands on strong pillars—precision, consistency, reliability, and compliance.

1. Dimensional Accuracy

At Noves Technologies, we place the highest importance on dimensional accuracy, ensuring every component is manufactured to meet precise specifications and tight tolerances.

2. Process Control

At Noves Technologies, we implement strict process control at every stage of manufacturing to ensure consistency, efficiency, and reliability. From raw material selection to machining each step is closely monitored using advanced systems and standardized procedures.

3. Documentation & Traceability

At Noves Technologies, we maintain complete documentation and traceability for every component, ensuring full accountability, compliance with industry standards, and transparency throughout the production cycle.

4. Certifications & Standards Compliance

At Noves Technologies, we strictly adhere to international certifications and industry standards, ensuring that every component meets global benchmarks for safety, precision, and reliability.