Scalable. Streamlined. Reliable.

At Noves Technologies, our production management system is designed to deliver precision with flexibility. We understand that industries like aerospace, medical, defence, and automotive require manufacturing processes that can adapt to varying volumes without compromising quality. That’s why we have developed a scalable production framework—whether it’s small-batch prototyping or large-scale production, we maintain the same level of accuracy, consistency, and reliability.

Our streamlined workflows integrate production scheduling, process control, inventory management, and quality checks, ensuring efficiency at every stage. By leveraging modern infrastructure, advanced CNC technology, and skilled expertise, we minimize downtime, reduce waste, and optimize resource utilization.

What sets us apart is our ability to deliver reliable outcomes, on time and at scale, with complete transparency and traceability. From concept to completion, our production management system provides clients with the confidence that every project will meet global standards while staying aligned with timelines and cost targets.

Our Capabilities

Production Capabilities

At Noves Technologies, our production capabilities cover everything from prototyping to high-volume manufacturing. With advanced CNC machines, skilled expertise, and strict quality control, we deliver components that meet tight tolerances, global standards, and client expectations.

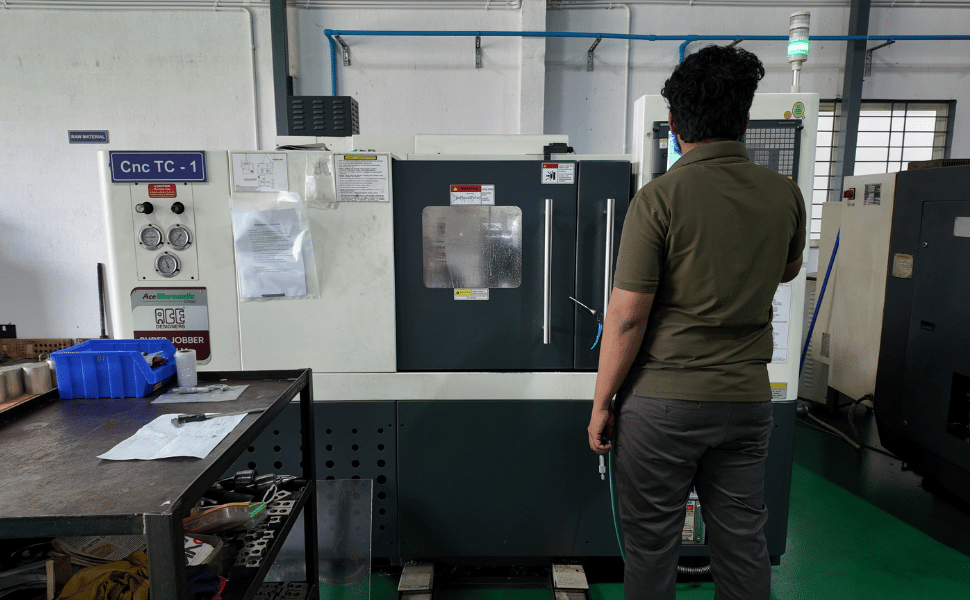

CNC & VMC Machining

Our advanced machines and skilled team enable us to handle complex geometries, varied materials, and both low- and high-volume requirements, ensuring reliable performance across aerospace, medical, defence, and automotive industries.

Batch & Volume Production

With flexible setups, advanced CNC systems, and streamlined workflows, we ensure consistent quality, cost efficiency, and on-time delivery—whether it’s prototypes or full-scale manufacturing.

Material Versatility

Our expertise in machining diverse materials allows us to deliver components that meet the unique performance, durability, and compliance requirements of aerospace, medical, defence, and automotive industries.

Assembly Support

Our team ensures fit, functionality, and reliability, helping clients reduce lead times and streamline their production processes.Precision but also integrated seamlessly into final products.

Real-Time Monitoring

We use real-time monitoring systems to track every stage of production. This ensures process transparency, quick issue resolution, and consistent quality, giving clients confidence that their projects are progressing exactly as planned.

Production Workflow

Our Production Workflow

At Noves Technologies, our production workflow is designed for efficiency, accuracy, and consistency. From material sourcing and machining to inspection and final delivery, every step follows a structured process to ensure on-time results and world-class quality.

Planning & Tooling Setup

By aligning resources, defining workflows, and preparing specialized tools, we ensure a strong foundation for efficient machining, accuracy, and smooth execution.

In-Process Quality Checks

This approach helps us detect and correct deviations early, ensuring consistent accuracy, reduced rework, and flawless final output.

Final Inspection & Documentation

Detailed documentation and traceability records are maintained to guarantee compliance, accountability, and confidence in product performance.

Packaging & Dispatch

Our tailored packaging solutions safeguard products during transit, while efficient dispatch processes guarantee safe, timely, and reliable delivery.

Why Choose Our Production Services?

Why Our Production Stands Out

At Noves Technologies, our production stands out because we combine advanced technology, skilled expertise, and disciplined workflows to deliver components that meet the most demanding industry standards. Every step is carefully managed to ensure efficiency, precision, and reliability, giving our clients complete confidence in the outcome.

-

⚙️ Advanced CNC & VMC machining for complex geometries

-

📊 Real-time monitoring for transparency and accuracy

-

🔍 In-process quality checks and strict final inspections

-

🗓️ Flexible batch and volume production capabilities

-

🛡️ Material versatility for aerospace, medical, defence & automotive

-

🚚 Reliable packaging, dispatch, and on-time delivery