Introduction

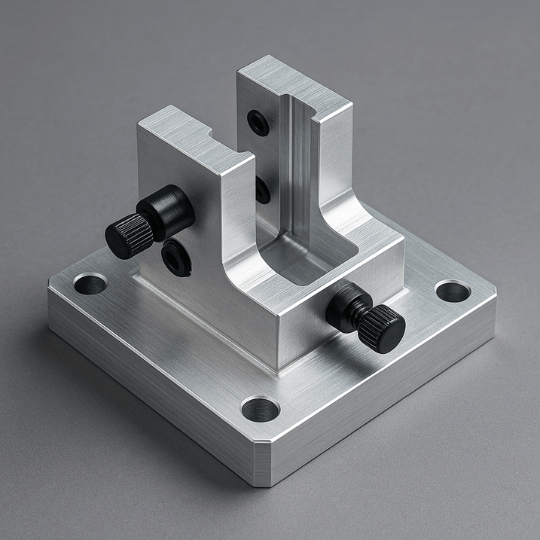

Our engineering team designs and builds robust, application-specific fixtures that support machining, assembly, and inspection operations. By reducing errors, improving repeatability, and streamlining workflows, our jigs and fixtures play a vital role in helping industries achieve higher productivity and superior quality standards.

Our Jigs & Fixture Solutions

-

🛠️ Custom Design – Tailored jigs and fixtures to meet specific applications

-

⚙️ Machining Support – Enhancing accuracy and efficiency in CNC operations

-

🔧 Assembly Fixtures – Improving consistency and reducing human error

-

🔍 Inspection Fixtures – Ensuring reliable measurement and quality checks

-

⏱️ Productivity Boost – Streamlined workflows for faster turnaround

-

✅ Durability & Reliability – Built with robust materials for long service life

Why Work With Us?

Why Choose Noves Technologies for Jigs & Fixtures?

-

🛠️ Tailored Solutions – Fixtures designed to match specific client requirements

-

⚙️ Advanced Engineering – Expertise in CNC-based and complex fixture designs

-

✅ Quality Assurance – Strict inspection for accuracy, strength, and reliability

-

⏱️ On-Time Delivery – Structured execution to meet client schedules

-

💡 Innovation Driven – Continuous improvement for better performance

-

🌍 Industry Versatility – Serving aerospace, medical, defence, and automotive sectors

Features and Benefits

Key Benefits of Our Jigs & Fixtures

-

🎯 Improved Accuracy – Ensures precise machining and assembly operations

-

⚡ Higher Productivity – Reduces cycle times and boosts efficiency

-

🔄 Consistency – Maintains repeatability across multiple production runs

-

🛡️ Reduced Errors – Minimizes human mistakes and rework

-

💰 Cost Efficiency – Saves time, material, and operational costs

-

🔧 Durability – Built with robust materials for long-lasting performance